21 Aug 2025 - 1 hour

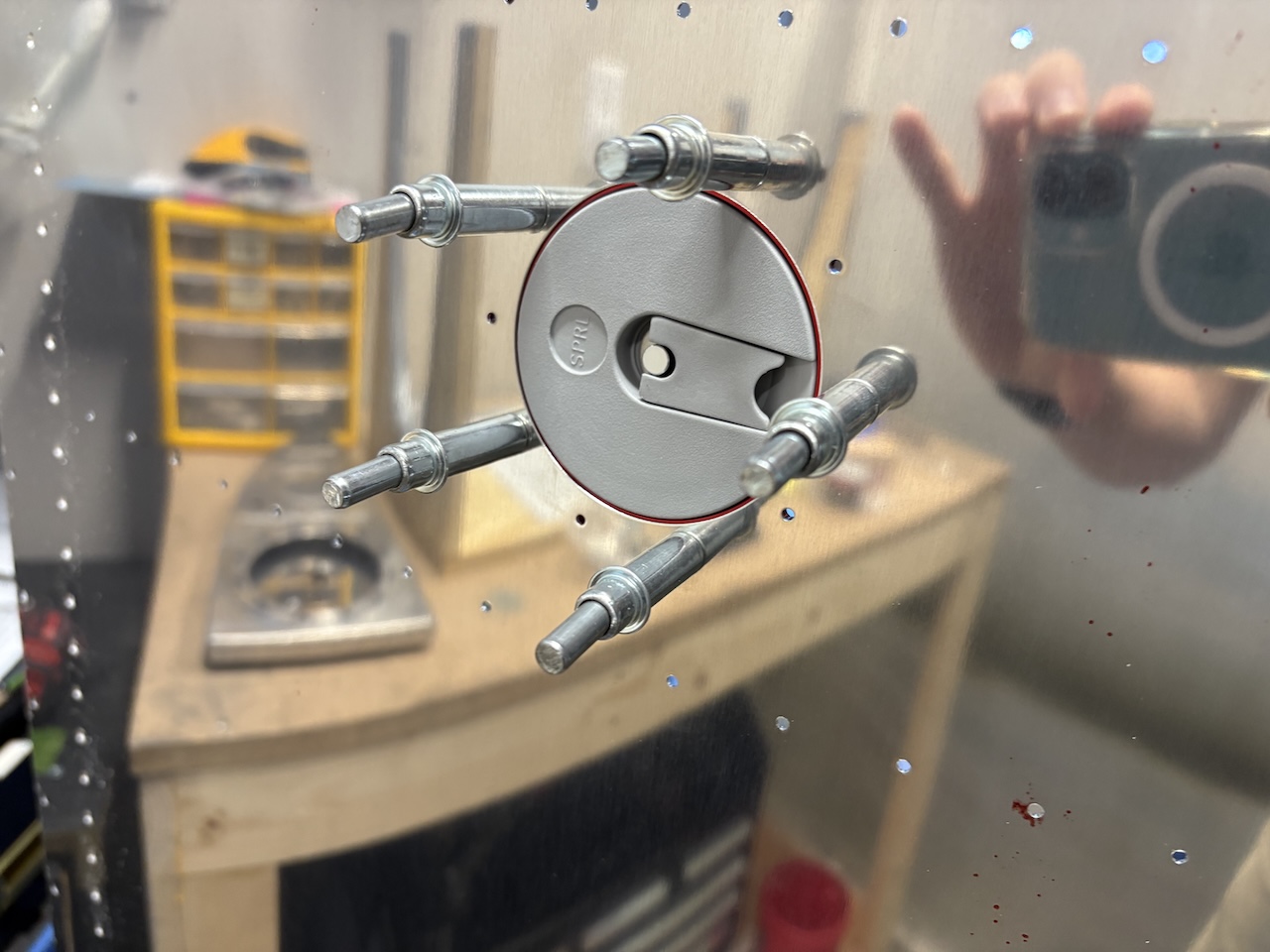

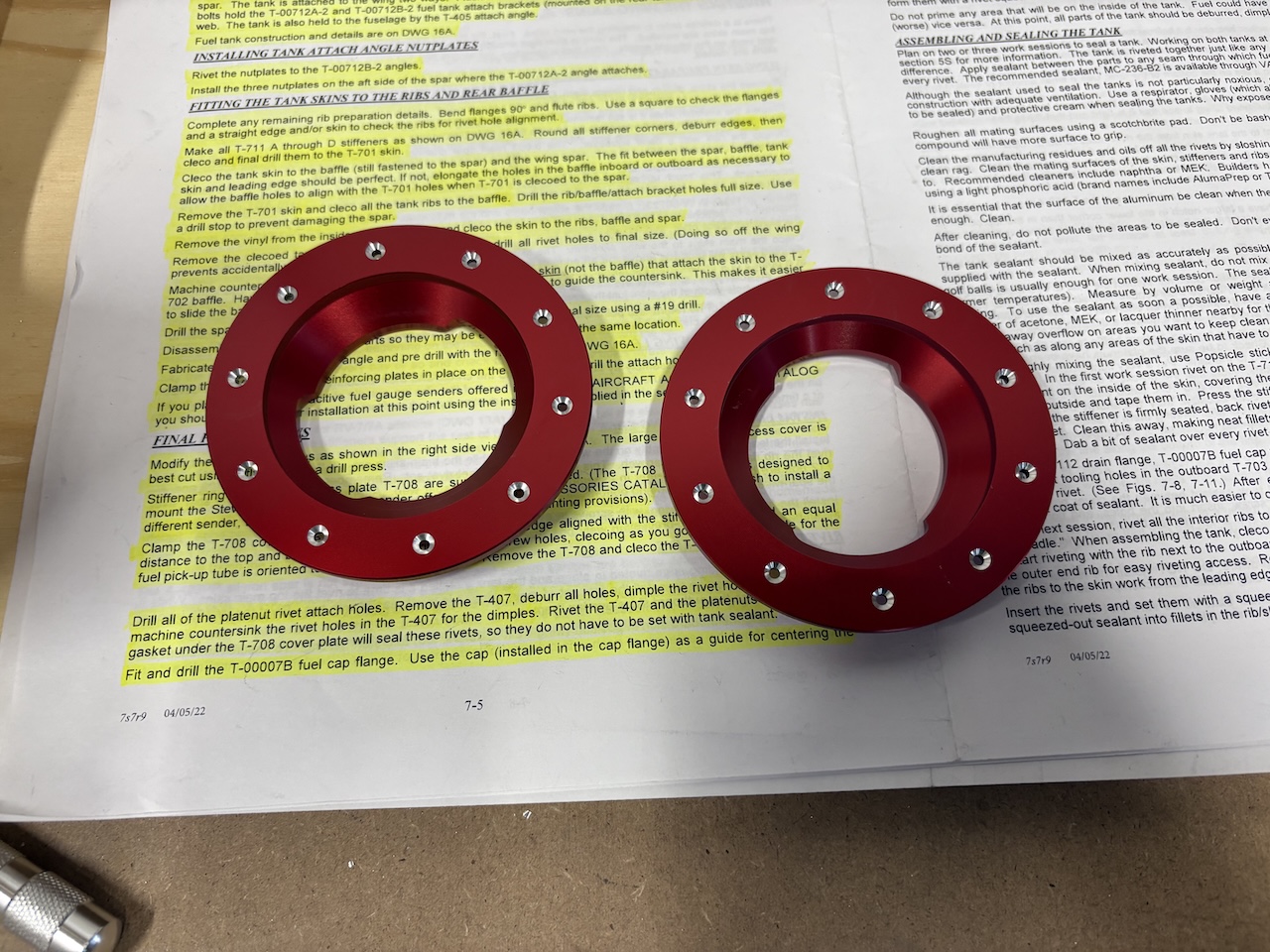

There are just a few things left before sealing up the tanks. Today, I match drilled the fuel tank caps. The flanges are now predrilled to match the holes on the skins, so there isn't much lining up to do. Just cleco them on and run the drill through them. Easy peasy.

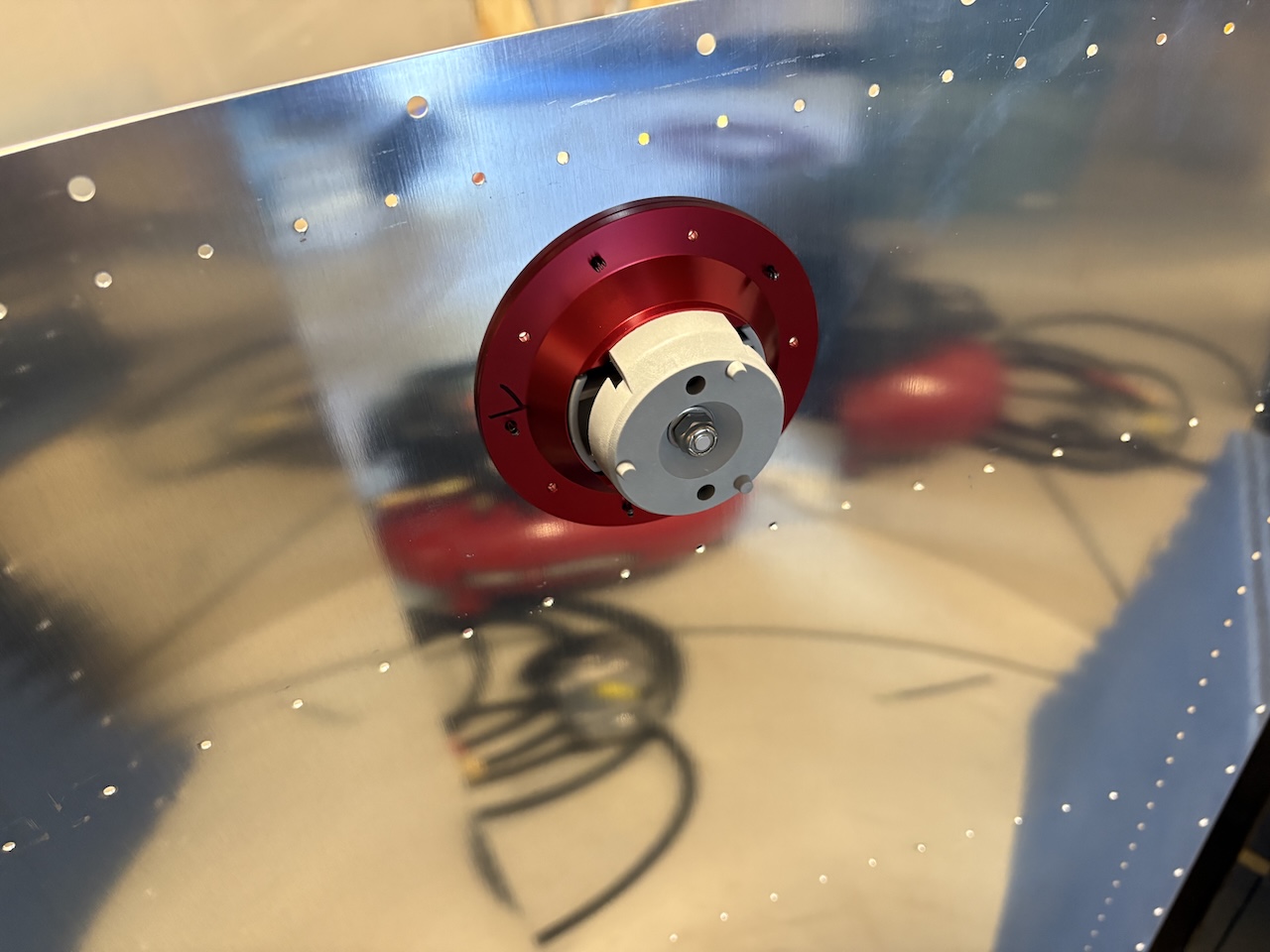

These new red milled and anodized flanges look really cool.

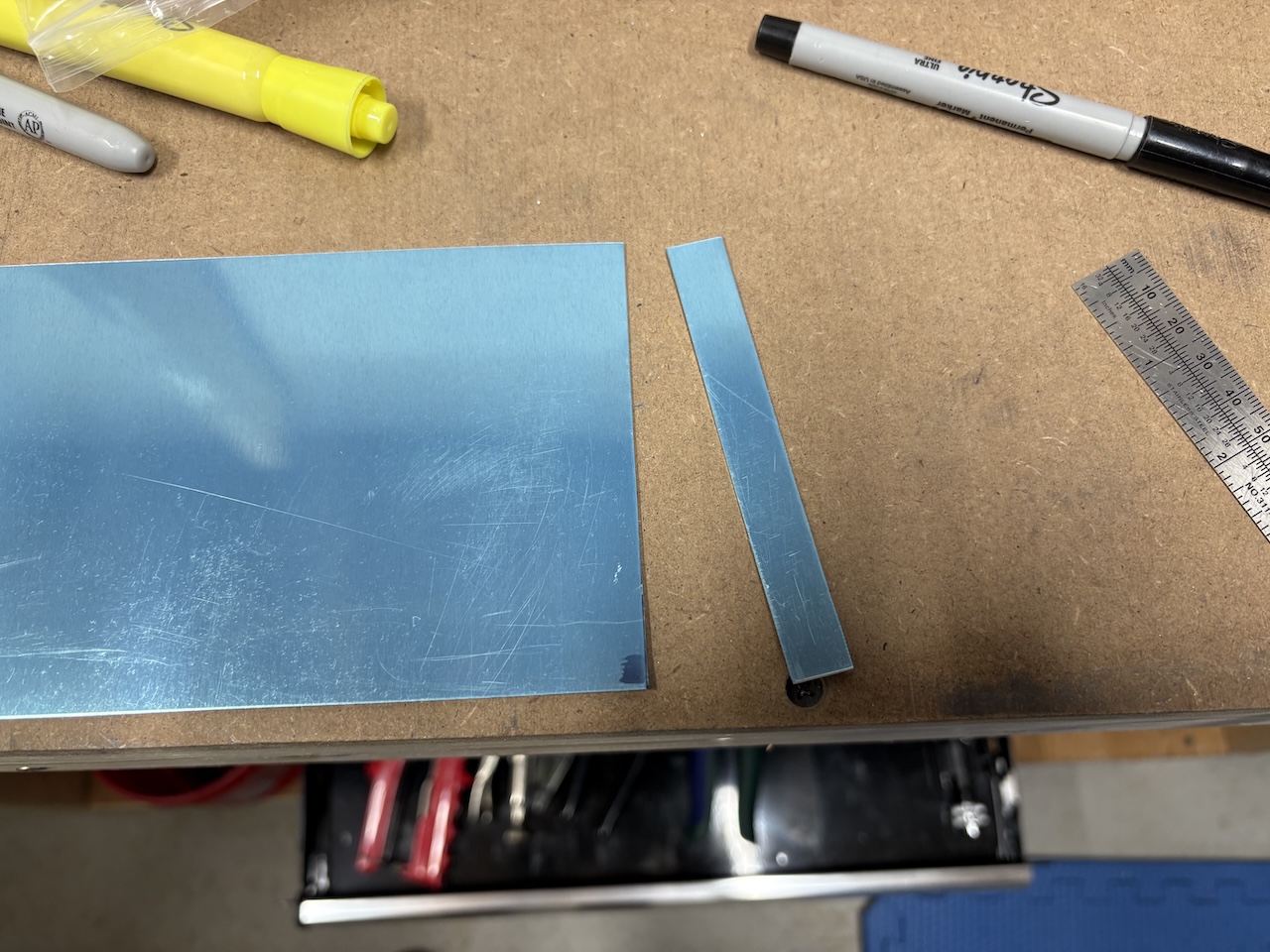

Then I made the tiny little brackets that hold the tank vent lines up at the highest point of the tank. First step was cutting a half-inch wide strip of 0.025" aluminum.

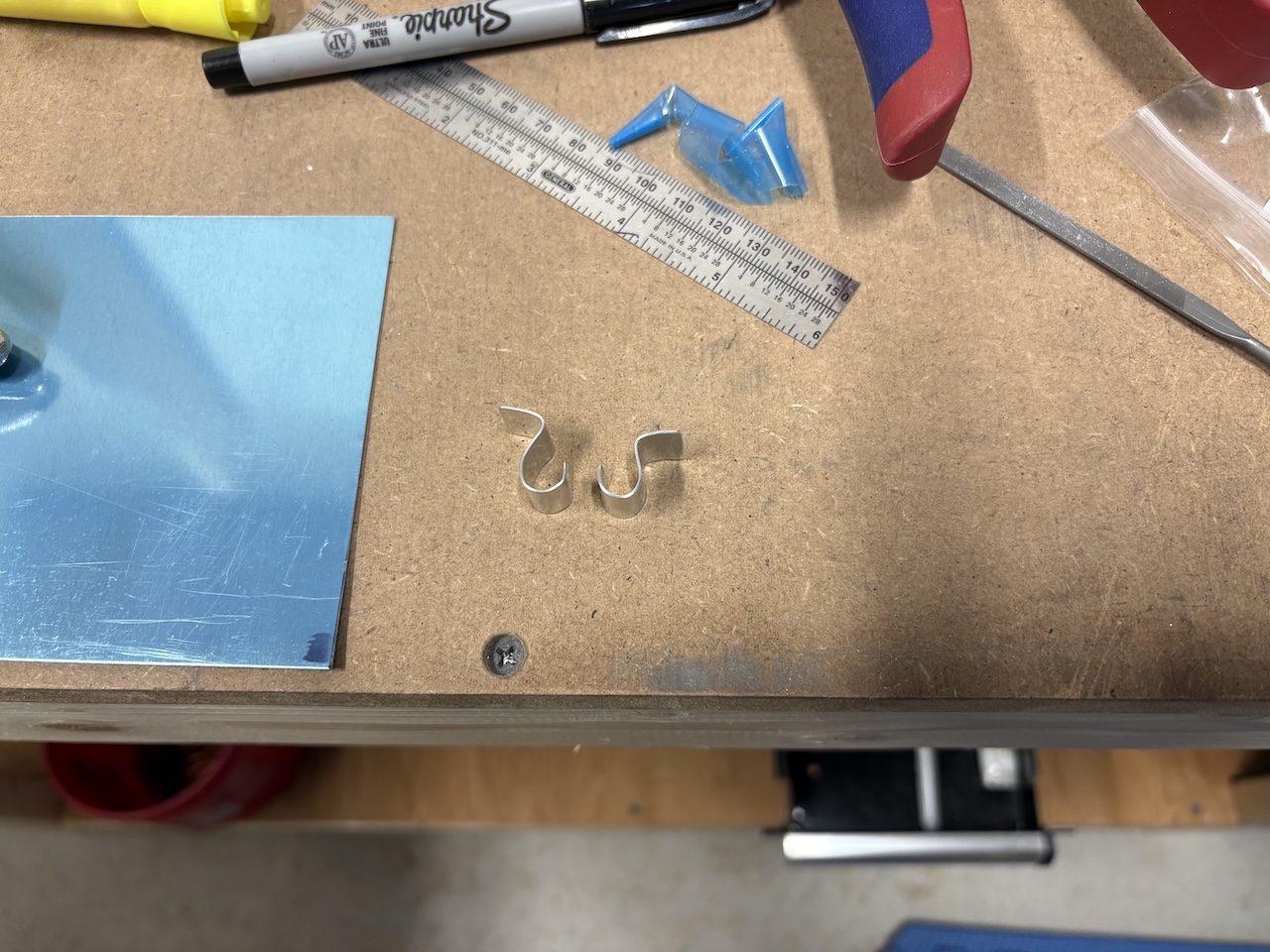

I bent them into shape using a pencil as a form for the round part and the hand seamers to help with the bending. Just going by eye on the 1:1 drawing on the plans here. It doesn't have to be exact, just something to hold the vent tube up in the top of the tank.

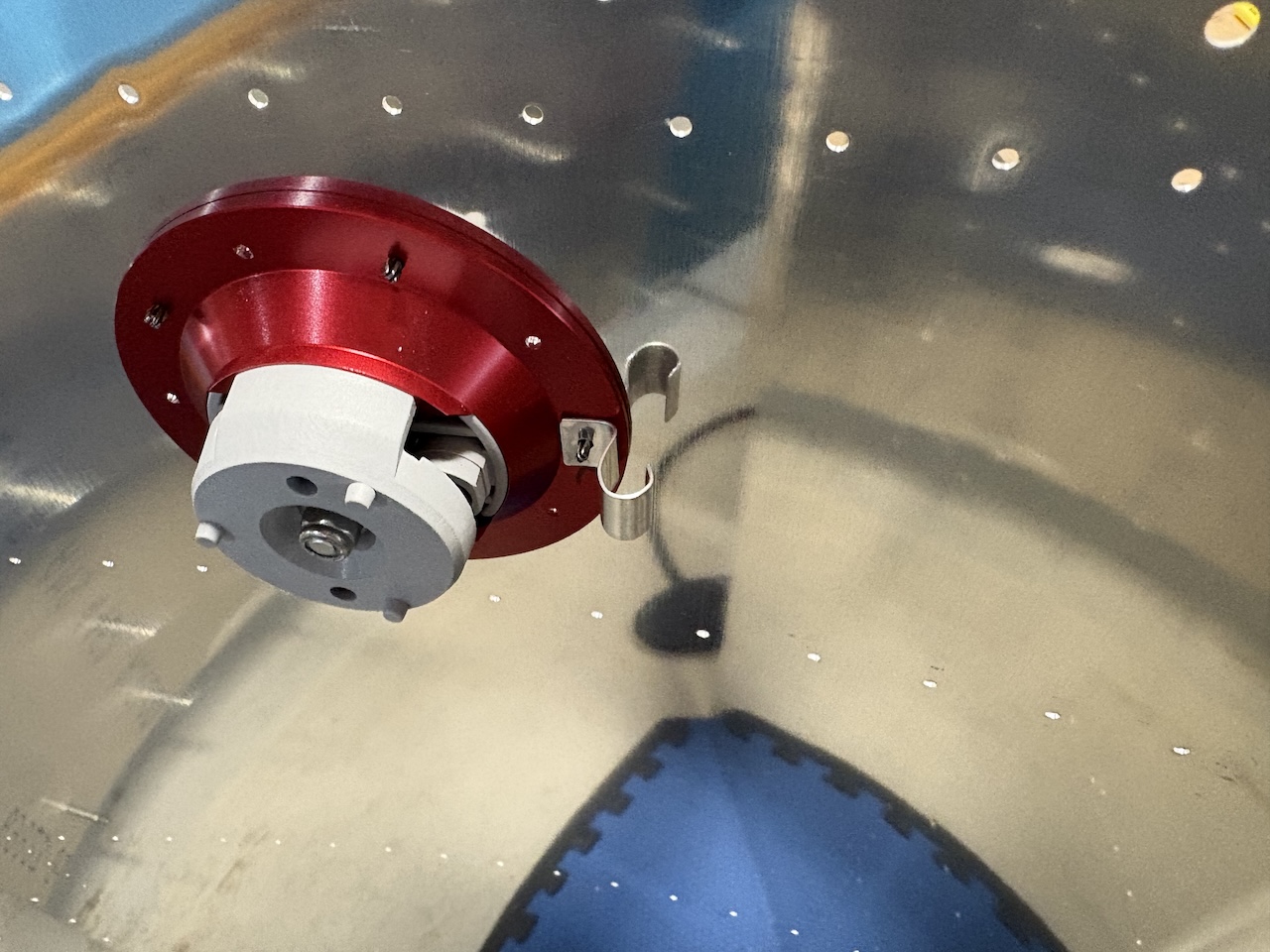

After drilling the mounting hole, I put it in for a test fit.

Then I countersunk the flanges to accept the dimples from the skin.

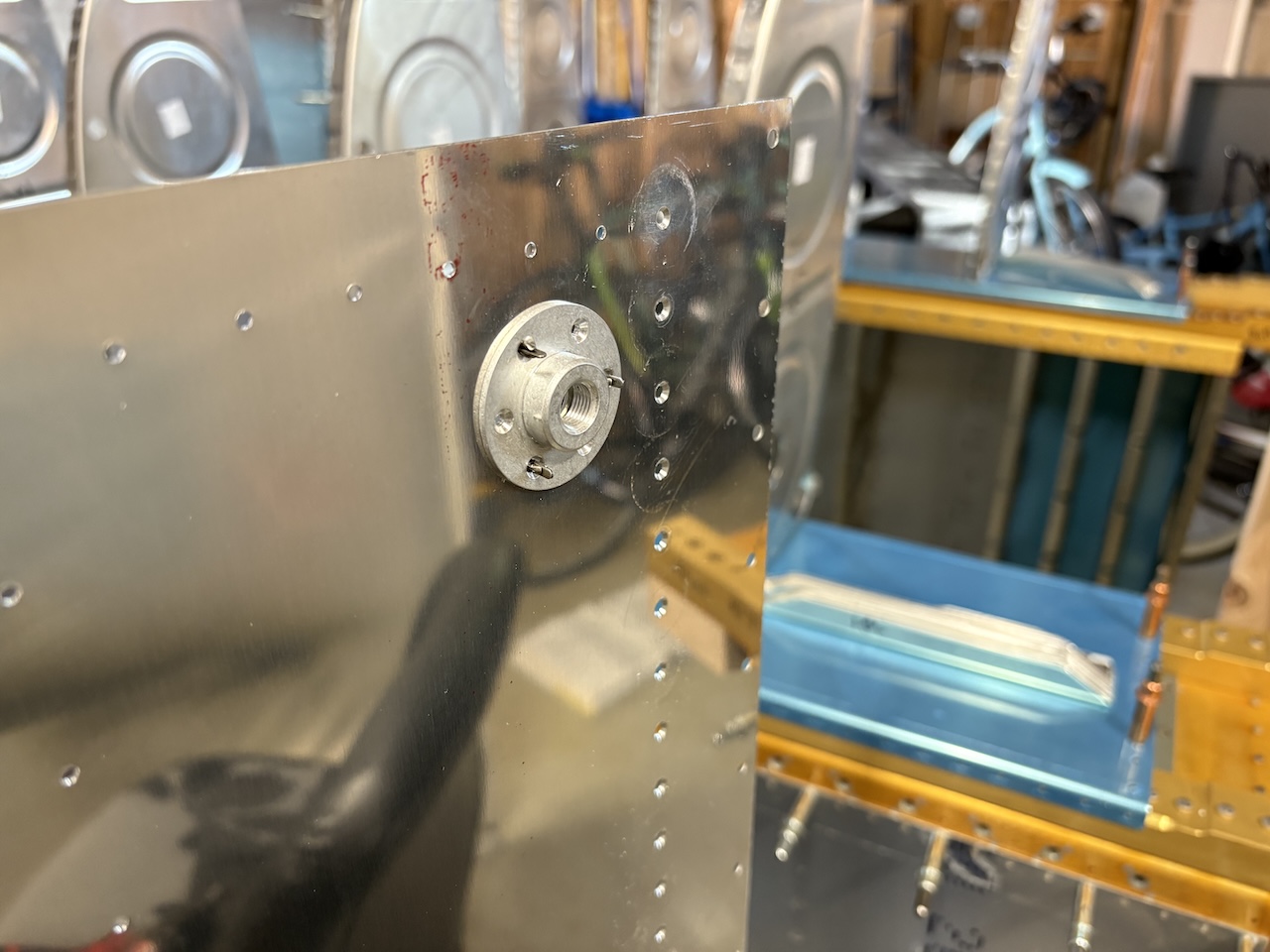

The last thing I did today was match drill the tank drain flanges to the skin. The flanges were already drilled and countersunk, so it was just an issue of lining up the drain holes and drilling through the rivet holes. The end of a fine-tip Sharpie fits almost perfectly in the drain holes so I used that to line everything up for drilling.

I ordered the tank floats, some tank sealant, wiring conduit, and other bits and bobs from Van's tonight so hopefully that package arrives soon so I can get to sealing up the tanks after I deburr and dimple everything!